Welcome To

Clean Steam

Steam Generators For All Clean, Critical, And Process Applications

CLEAN STEAM is your revolutionary design solution in steam generators/boilers. All of the Infinity/Clean Steam units provide for less than half the size and cost of standard boilers/generators.

Clean Steam generators for all clean, Critical and process applications

- Clean and Pure Design

- Packaged Designs

- High Pressure Designs / Explosion Proof Designs

- Modular and Mobile Designs

Clean Steam Generators

With all Infinity Clean Steam units, there will be “pure” and “clean” steam production capable of industry standards with respect to GMP requirements and their ability to produce steam and condensate capable of direct injection, WFI production and clean room humidification.

All Infinity Clean Steam units can be used in applications that require the ultra pure aspects of non-supportive biological growth and can be used in or toward all critical Pharma and Bio-Tech applications.

They are capable of producing pyrogen-free and endotoxin-free steam. The output from our generators meets all U.S. Pharmacopeia (USP) requirements for use in autoclaves, critical area humidification, routine steam-in-place (SIP) sterilization and many other biotechnology manufacturing processes.

Electric Pure Steam Generators and Clean Steam Generators

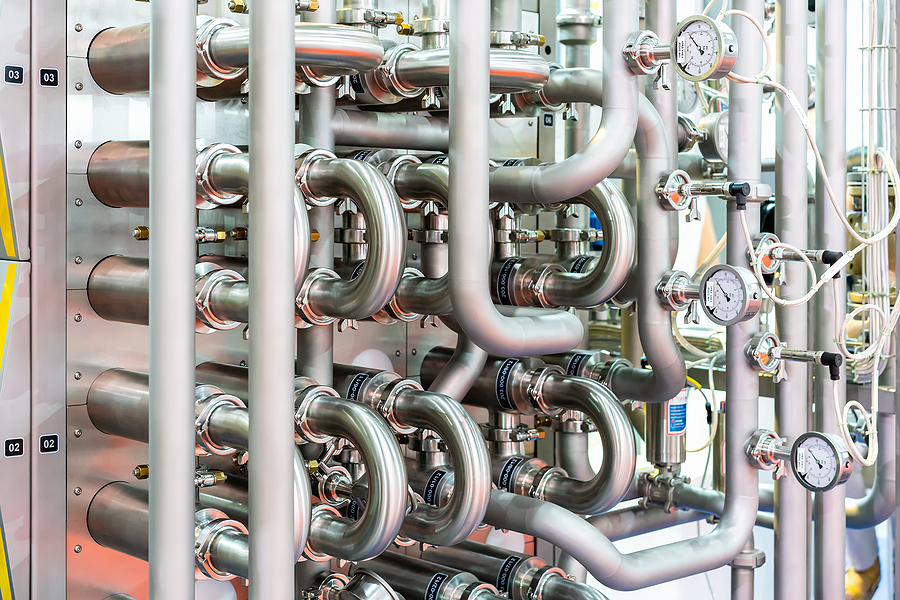

Infinity Electric CLEAN STEAM Generators & Electric Pure Steam Generators can be equipped with sanitary ASME pressure vessels made from 316L stainless steel. All connections on the vessels including the heating elements are sanitary with full drainability.

All wetted components in contact with the water/steam media is 316L with sanitary components and connections.

Simple Design, Range of Sizes

Infinity Clean Steam Generators are designed for fit and function in mind. The most compact and flexible design available on the market provides equipment manufacturers the ability to create equipment that is:

- Less Expensive

- Smaller/more compact

- More efficient

- Faster -and- More Durable

Wide ranging standard sizes will meet most application requirements, but Infinity can just as easily and economically create a perfect fit for your application. From CE/UL/ASME/etc. we can provide the right product that will set your process or product apart from the norm.

Clean Steam Condenser Attachment for WFI

WFI Condenser unit for all Clean Steam systems

All Infinity Clean Steam units can be modified with a Water For Injection (WFI) Generator. Increasing the usefulness of the nearly instantaneous steam generator units. Take advantage of the instant nature of the Infinity Clean Steam units by not only creating near instant Clean Steam, but ultra pure WFI product for all your ultra pure system requirements. Benefits:

- Near Instant production of steam and WFI

- Ultra Pure steam at ultra low cost

- Most compact production units available

Pharmaceutical-grade Steam At Unprecedented Economy

All Infinity biopharmaceutical steam generators is designed with either a Temp or Pressure PID loops for precise control of the clean steam system.

INFINITY’S Clean Steam and Pure Steam generators are designed to produce biopharmaceutical grade USP, EP, JP, CP clean steam used in the biotechnology, pharmaceutical and life sciences manufacturing processes. Incredible economy, size, power and design makes the Infinity Clean Steam Units provide product and function never before seen in the Clean industries.

From 1 lb/hr to 10,000 lbs/hr Infinity Clean Steam units allow systems to be produced in previously unforeseen size and economy. Ultra Pure Sanitary construction allows for use in all clean markets from Pharma-Bio-Food.

Infinity’s Clean and Pure steam generators are designed in accordance with cGMP and BPE standards. Fully drainable and ease of access for cleaning and maintenance makes units perfect for the end user or the OEM looking to gain a advantage over their market competitors.

GMP Guidelines

GMP guidelines use the term ‘clean steam’ without giving greater details or explanation. A Clean Steam Generator’s quality is defined by its use and the quality of the steam it produces in the form of regulated standards and pharmacopoeias. In many applications pure steam and clean steam are one-in-the-same from a pharmaceutical requirement. It is defined in the USP for the first time in the year 2006 and referred to as pure steam. Quality of this steam is defined by the condensate which must have WFI quality. Steam quality is applied for the sterilization of primary packaging material for sterile packets and forms or for the sterilization of equipment parts in contact with the product during sterile production.

Clean Steam Generators

All Infinity Clean Steam units can be modified with a Water For Injection (WFI) Generator. Increasing the usefulness of the nearly instantaneous steam generator units.