Infinity Steam Generators and Clean Steam Generators

INFINITY STEAM GENERATORS AND CLEAN STEAM GENERATORS allow the most cost effective production of process steam or pure and clean steam from all sources, for all applications.

Specializing in point of use and process specific designs, custom, and OEM product designs, allowing for simple and fast installation, and operation.

WFI (Water for Injection) production. All of our units can be converted with a condenser coil that will allow for the production of ultra pure WFI. Simply identify the volume of water per hour required for your application and Infinity will provide the necessary product for your system.

Pharmaceutical to Semiconductor and Food to Petrochemical, Infinity’s steam generators offer near instantaneous production of steam with the most compact inexpensive design available on the market.

The Infinity steam units offer efficiencies never seen in the industry, allowing units to get to temperature and pressure in 2 minutes not 20+ minutes, and seconds from a warm start.

Pharmaceutical Clean Steam

Pharmaceutical processing and machinery development requires the cleanest of materials but the most process stable components available. Creating steam is a demanding application for all electrical heating equipment and keeping the system free from contaminates is critical. With all Infinity steam units the heater bundles used to create the steam are all of sufficiently low watt density to ensure there is not shedding of heater component materials into the media via the over heating of surface temperatures which destroy the oxide layers which make stainless steels “stainless”.

WFI (Water for Injection) production. All of our units can be converted with a condenser coil that will allow for the production of ultra pure WFI. Simply identify the volume of water per hour required for your application and Infinity will provide the necessary product for your system.

All CLEAN STEAM requirements and process conditions can be observed with the Infinity CLEAN STEAM units. All Infinity ultra pure components used in the manufacture with the ultra low watt density heaters designed into the system make the purity of product and construction perfect for all industry and market standards.

- USP process and production component (United States Pharmacopeia)

- BP production component (British Pharmacopoeia)

- EP production component (European Pharmacopoeia)

- JP production component (Japanese Pharmacopoeia)

Clean Steam Generators

Product sizing from, point of use for small process 5-33 lbs/hr applications to boiler room equivalents 500-3000 lbs/hr.

Infinity Pure Steam Generators are designed to replace cumbersome designs and save space and power by using the “On-Demand” ability of the Infinity CRES heater elements. With all Infinity steam generators, the units can achieve times to temp in @1-2 minutes from a cold start, and nearly instantaneous from a warm or hot start, no “Stand-By Idling” is required.

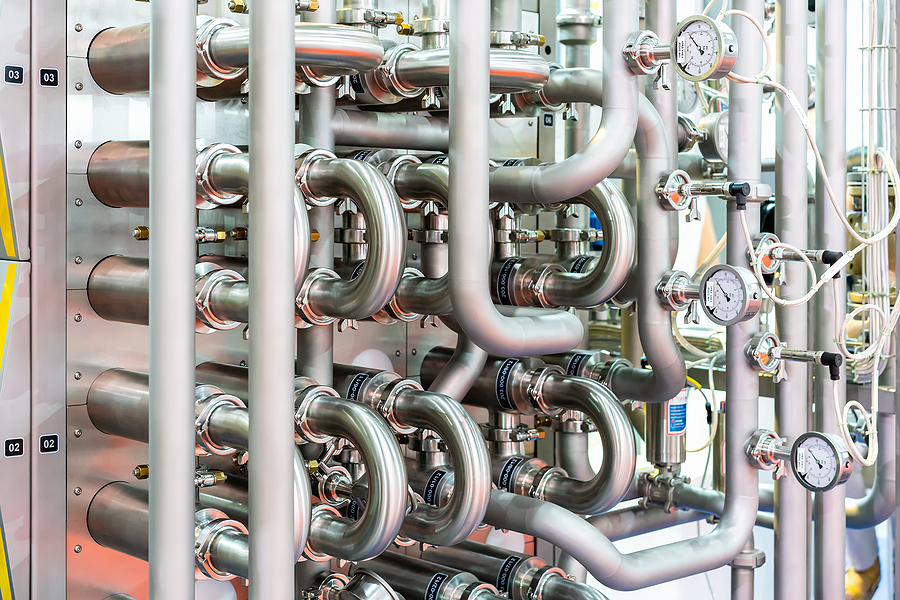

Infinity Pure Steam Generators come standard with ultra low watt density sanitary 316lL stainless steel heating elements and ultra pure pressure housings. The ports and adapters on the housing allow for fully drainable contacting surfaces. All wetted components in contact with feed water and clean steam is 316L polished stainless steel.

Life Science Clean Steam

CLEAN STEAM GENERATORS: Compact/Powerful/Economical/Ultra-Pure

Infinity CLEAN STEAM generators are designed to produce bio-tech, bio-pharma, and all life science grade steam for all critical applications. Production of materials related to the Unites States Pharmacopeial Convention.

WFI (Water for Injection) production. All of our units can be converted with a condenser coil that will allow for the production of ultra pure WFI. Simply identify the volume of water per hour required for your application and Infinity will provide the necessary product for your system.

All CLEAN STEAM requirements and process conditions can be observed with the Infinity CLEAN STEAM units. All of the ultra pure components used in the manufacture with the ultra low watt density heaters designed into the system make the purity of product and construction perfect for all industry and market standards.

- USP process and production component (United States Pharmacopeia)

- BP production component (British Pharmacopoeia)

- EP production component (European Pharmacopoeia)

- JP production component (Japanese Pharmacopoeia)

The Infinity CLEAN STEAM products provide best in class separation, durability and reliability. Communications with plant equipment is simple with standard Ethernet protocols/Modbus/RS Comms, etc.

All Infinity CLEAN STEAM units are produced in accordance with current Good Manufacturing Practices, and BPE standards, allowing for no entrapping surfaces and full sanitary connections. All units come standard with our closed-loop process control system that can be controlled via temperature or pressure depending on the application and market. Sampling ports can be included in all of our product offerings and infinite control or maintenance components or modifications can be added to meet your most demanding processes.

Semiconductor and Solar Cell Manufacturing Clean Steam

UHP steam, (Ultra High Purity) is used in many areas of industry, that require oxidation or annealing of precision and critical parts. These processes are designed for creation of oxide layers for silicon wafers, semiconductor and growth or layering/build up applications. These layers help compliment the passivation or inert aspects of a material during a machining or heat treatment process.

WFI (Water for Injection) production. All of our units can be converted with a condenser coil that will allow for the production of ultra pure WFI. Simply identify the volume of water per hour required for your application and Infinity will provide the necessary product for your system.

Oxidation and annealing represent a critical process step in many electronic component processes, solar cell production and semiconductor implementation.

CLEAN STEAM allows for efficiency improvements related to processing times, reduction in manufacturing steps, increased throughputs and improved quality.

CLEAN STEAM and UHP steam are used in critical industries from MEMS, Nanotech, Photovoltaics, Semiconductor, MEMS, etc. Processing for depositions, annealing, release etching and bonding, cleaning and heating.

Industrial / Oil / Gas / Chemical Industries

Infinity CLEAN STEAM SYSTEMS are economical choices for all applications including Industrial and Petro-Chem industries.The natural benefits of our electric steam generators and steam heat exchangers make designing your processes and systems more compact and efficient than ever before.Infinity CLEAN STEAM systems allow for instantaneous generation of steam from cold starts compared with all other technologies. Stand-by idling and firing up your plant boiler to simply heat or process a small operation on your production floor is no longer necessary with the Infinity line of product. From point of use steam generator units to high production systems, Infinity offers a product to improve all of your applications. WFI (Water for Injection) production. All of our units can be converted with a condenser coil that will allow for the production of ultra pure WFI. Simply identify the volume of water per hour required for your application and Infinity will provide the necessary product for your system.

FOOD AND BEVERAGE Clean Steam

- Infinity Pure Steam Generators are designed to replace cumbersome designs and save space and power by using the “On-Demand” ability of the Infinity CRES heater elements. With all Infinity steam generators, the units can achieve times to temp in @1-2 minutes from a cold start, and nearly instantaneous from a warm or hot start, no “Stand-By Idling” is required.

- WFI (Water for Injection) production. All of our units can be converted with a condenser coil that will allow for the production of ultra pure WFI. Simply identify the volume of water per hour required for your application and Infinity will provide the necessary product for your system.

- The CLEAN STEAM line of heater can be used for all production processes, from heating, humidity, hydration, cooking, cleaning or any consumables processing system.

- All units come standard with sanitary connections, or can be provided with any standard industry fitting arrangements, including compression, flanges, vcr, threads, etc.

- Clean In Place (CIP) applications where instantaneous and mobile steam generators need to be used to heat processes or steam jackets make all CLEAN STEAM units perfect for these critical applications.

- Steam In Place (SIP) applications where instantaneous and mobile production of steam for critical manufacturing processes give the compact and natural benefits of the Infinity products application where all other oversized customary boiler units are now unnecessary.